Market Leader

Excellent quality

Quick delivery

Specials

Description

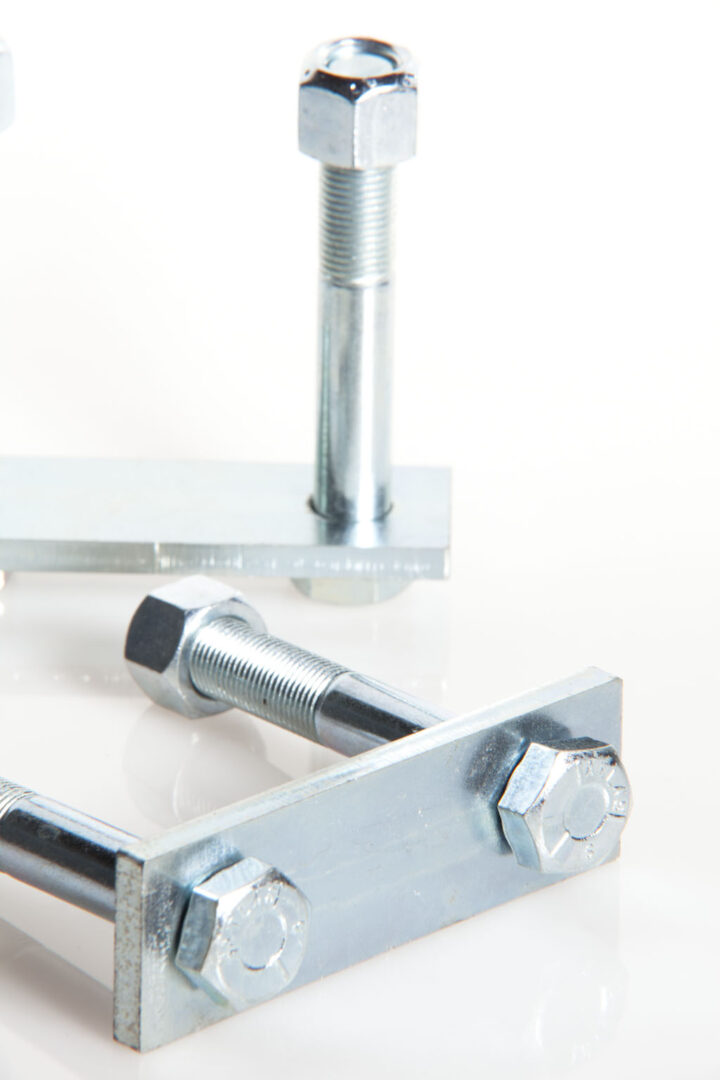

These bolts and nuts for the mounting of the scrapers Nijhuis X and XL belong to an optimal mounting set. The life of the hair removal scrapers is optimized by mounting them correctly in the machine. The corresponding special bolts and nuts UNF and fine thread ensure optimum securing of the scratching block. This causes no movement. This prevents the risk of breaking and tearing the product.

UNIQUE FASTENING SYSTEM FOR A DURABLE PRODUCT

Our Nijhuis Group rubber scraper blocks are wear-resistant and resistant to animal fat, urine and disinfectants. The scrapers are made of extra strong galvanized steel. As a result, they remain sharp and do their job for a long time. The scratching blocks have a specific structure and consist entirely of nylon layers that are inlaid in natural rubber. Due to the specific density of the natural rubber, the product remains flexible and has a strong structure. The hair removal scrapers therefore have a much longer lifespan than others. In combination with our special mounting set, you therefore have an optimal cost-saving overhaul set in your hands.

CUSTOMER RETENTION THROUGH QUALITY, SPECIAL VERSIONS AND DELIVERY SPEED

Nijhuis Group makes and sells high-quality overhaul parts for slaughter machines, such as mounting sets for scratching blocks. We are specialist in pig hair removal and make different kinds of parts for pig hair removal with high quality so that they last for a long time. We do this with our many years of Nijhuis slaughter technology knowledge. Large and small slaughterhouses all over the world belong to our clientele. They choose our products because of the exclusive quality, customization, service and the long life of the parts. With this, our customers opt for productivity and sustainability. We monitor our quality with great care. Raw materials are supplied with food safety and REACH certificates. In addition, our suppliers are all locally based. Our sustainable quality products thus contribute to the prevention of disruptions in the slaughter process. The total slaughter costs in the pig hair removal chain are also reduced.

We also keep the customers we have. They choose our products first of all to properly set up the basis in the hair removal process. Slaughterhouses are slaughtering more and more pigs with the same slaughter line. As a result, the parts in the hair removal machine have to endure more and more. Optimal hair removal of the pigs is essential in the slaughtering process. If a pig is not properly clean, the slaughter line is shut down. The quality and durability of the spare parts is therefore becoming increasingly important.

Additional information

| Dimensions | 95 x 35 x 6 mm, Bolts M12 & M14, UNF 1/2'' x 3'' |

|---|---|

| Article code | NMBS1210 |

| Version | Electrolytically galvanized steelwork |

| Packing unit | 100 pieces |

Oops! We could not locate your form.

Reviews

There are no reviews yet.