Market Leader

Excellent quality

Quick delivery

Specials

Description

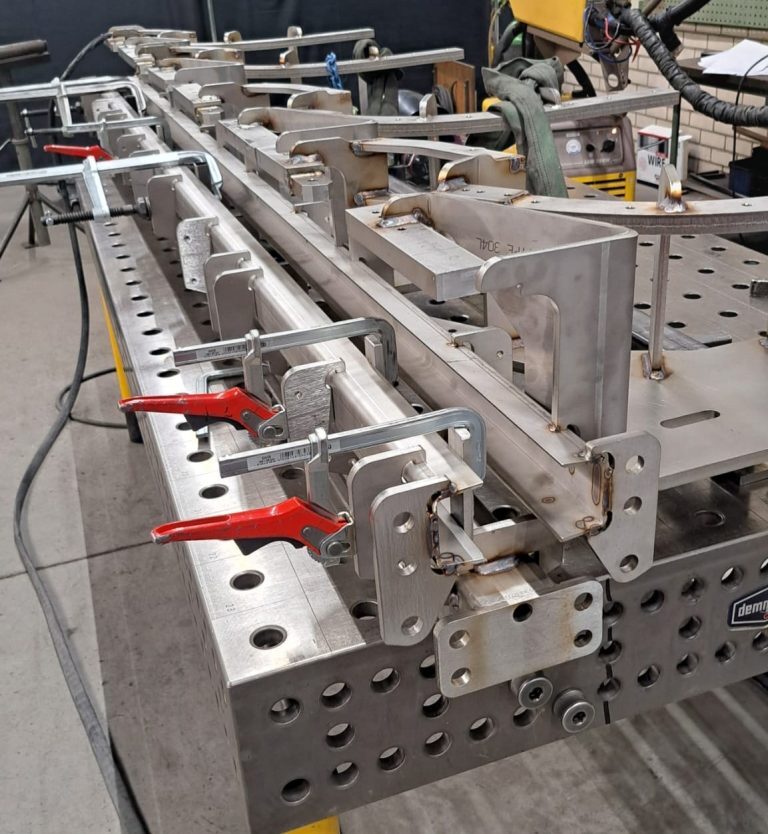

Food industry constructions

Did you know that making food industry constructions is a profession in its own right? The industry is driven by the strict standards and regulations that govern food safety and quality. This requires specific materials, designs and manufacturing processes that ensure food products are safe for consumption. The combination of these factors makes food industry products and processes both complex and unique, requiring a specialized approach in both design and execution.

What can we make for you?

From conveyors, boilers, complete mechanical engineering to spare parts for pig dethatching machines; our team knows this industry! Are you looking for a skilled partner to temporarily scale up your production capacity? Then it is possible to outsource complete and/or parts of machines and constructions of rubber, stainless steel, aluminum and steel to us. Because of our years of experience, we can quickly make a new product our own, making it advantageous to outsource.

Innovation, knowledge and quality

At Nijhuis Group, we are proud of our role as a leading specialist in making advanced machinery, machine parts for pig deboning and structures for the food industry. These include boilers, platforms, conveyors and all kinds of specific products, such as organ trays and showers, for slaughter techniques. With a rich history in slaughter techniques and a strong focus on innovation and technology including robotizing (our own) production processes, we are your trusted partner for solutions that promote efficiency, quality and sustainability in the food processing industry.

Additional information

| Delivery time | 1 – 2 weeks |

|---|---|

| Material | (Stainless) steel, alumininium |

Oops! We could not locate your form.

Reviews

There are no reviews yet.